POLYETHYLENE 0035

HB0035 is a high molecular weight high density polyethylene blow moulding grade combining blow

moulding extrusion behavior and superior mechanical properties. Blow moulded items made from HB

0035 exhibit high impact strength and good stress cracking resistance and high stiffness. HB 0035

contains antioxidant to protect the polymer from degradation during processing.

HB 0035 is a highly crystalline, non-polar thermoplastic and has excellent chemical resistance and

superb impact resistance at ambient conditions and even at cold temperatures.

POLYETHYLENE 52518

POLYETHYLENE 7000F

POLYETHYLENE EX5-GM-9450-F

"EX5 (GM 9450 F) is a high Density polyethylene with Butene-1 as comonomer.

It is a high molar mass for blown film with in comparison to EX4 lower stiffness and increased tenacity.

The product has good toughness, low gel level and good tear strength.

Stabilization: Ca-Stearate, Zn-Stearate, Irgafos 168v

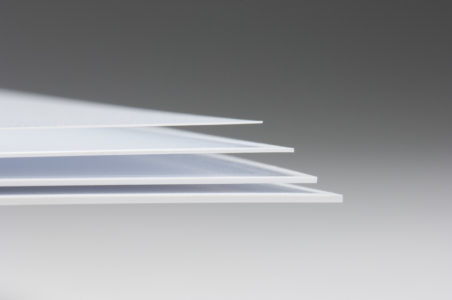

POLYETHYLENE HDPE-LLDPE

POLYETHYLENE HM-CRP100-Black

HM-CRP100 Black is a black pipe grade resin (PE100) which is manufactured by suspension polymerization of

ethylene monomer, HM-CRP100 Blue is a bi-modal high density polyethylene with 1-Butene as comonomer.

Technical Data

HDPE: HMCRP100N Black (PE100 Black)

Characteristic Properties Black PE100 resinDensity: 0.955-0.959 g/cm3

Main Applications Top quality PE100 pressure Pipes for gas and water transportaion at higher pressures or with thinner walls as PE8ODensity: 0.946-0.950 g/cm3

Additives Antioxidant/Process stabilizer Lubricant (processing aid)/ acid scavengerPOLYETHYLENE HM-CRP100N-PE100

HM-CRP100N (PE100) is a natural pipe grade resin which is manufactured by suspension polymerization of

ethylene monomer, HM-CRP100N(PE100) is a bi-modal high density polyethylene with 1-Butene as comonomer.

Technical Data

HDPE: HMCRP100N (PE100)

Characteristic Properties Natural PE100 pipe resinDensity: 0.946-0.950 g/cm3

Additives Antioxidant/Process stabilizer Lubricant (processing aid)/ acid scavengerDensity: 0.946-0.950 g/cm3

Main Applications Top quality PE100 pressure Pipes for gas and water transportaion at higher pressures or with thinner walls as PE8O (UV stabilization and/ or pigments during precessing)POLYETHYLENE HM9450-EX5

POLYETHYLENE LL-0209-AA

"LL 0209AA" is a LLDPE copolymer with butene as

comonomer which contains antioxidant.

It is recommended for general purpose applications.

It is suitable for blending with conventional LDPE.

Film made from pure LL 02090 AA has the following

advantages over conventional LDPE:

Better sealing.higher puncture resistance.

Greater drawdown capability.

Higher tensile strength.

Neutralizer: Calcium Stearate.

Antioxidant: Irganox1010, Irganox168

POLYETHYLENE LL-0209-KJ

"LL 0209KJ" is a LLDPE copolymer with butene as

comonomer which contains antioxidant, Slip and

antiblock additives.It gives film of high slip which is easily

separable.

It is recommended for general purpose applications. It is

suitable for blending with conventional LDPE

Film made from pure LL 0209 KJ has the following

advantages over conventional LDPE:

Easier sealing. Greater drawdown capability. Higher

tensile strength. Higher puncture resistance.

POLYMER ABS

POLYPROPYLENE Z-30-s

Z30S is widely used for the production of bulked continuous filament for carpet face yarns. Another major application is the production of high tenacity continuous filament for straps for backpacks, handles for big bags and safety belts. Continuous filament with medium tenacity is used for upholstery, sportswear and heavy duty clothing. Moplen Z 30 S is al also suitable for the production of low denier staple fibres for thermobonding.